The Rise of Automatic and Adjustable Shock Absorbers: What It Means for OEMs

Global manufacturing is shifting toward smarter, more adaptive systems, and motion-control components are no exception. Traditional fixed-rate shock absorbers are giving way to automatic and adjustable damping solutions designed to improve stability, extend equipment life, and optimize performance across varied operating conditions.

For OEMs competing in demanding sectors like heavy machinery, automotive, material handling, and industrial automation, the evolution from fixed to adjustable damping is more than a technical upgrade; it’s a strategic advantage.

Why Adjustable Shock Absorbers Are Growing in Popularity

Several industry trends are accelerating the adoption of adjustable and automatic shock absorbers:

Greater Need for Versatility Across Applications

Modern machinery often performs diverse tasks under different loads, speeds, and environmental conditions. Adjustable dampers allow OEMs to fine-tune damping characteristics, reduce shock impact under fluctuating loads, and improve stability across machine cycles. This flexibility is particularly valuable for construction equipment, warehouse automation, industrial robotics, and commercial vehicles.

Pressure to Reduce Maintenance Costs

OEMs and end-users are seeking components with longer service life, lower breakdown frequency, and minimal lubrication or maintenance. Automatic dampers that self-adjust based on velocity or load help reduce stress on mechanical systems, extending component lifespan and lowering the lifetime cost of ownership.

Rising Expectations for User Comfort and Safety

In sectors like commercial vehicles, off-road machinery, or material handling, ride quality and operator comfort have become core purchase drivers. Variable damping provides smoother motion, enhanced operator control, reduced vibration transfer, and lower risk of fatigue-related errors. This directly contributes to compliance with ergonomic and safety standards.

Increasing Adoption of Smart and Autonomous Systems

With Industry 4.0 pushing the industry toward smart automation, dampers that adapt automatically without manual tuning are becoming essential. OEMs are integrating shock absorbers with load-sensing mechanisms, speed-sensitive valves, and electronic control modules in advanced systems. This enables real-time adaptation, a key requirement for automation-heavy industries.

How Adjustable Shock Absorbers Work

Though designs vary, most adjustable or automatic shock absorbers use one or more of the following mechanisms:

-

Adjustable Orifice Valving

A simple mechanical adjustment that allows engineers to increase or decrease fluid flow. It changes damping force based on the use case and is ideal for equipment needing tuning during installation.

-

Self-Regulating (Automatic) Valves

These react automatically to velocity or impact force without the need for manual intervention. They are optimized for varying load conditions and useful in high-throughput environments.

-

Electronic or Semi-Active Damping (Advanced Systems)

Sensors monitor load, motion, or speed while electronic control units adjust damping in real time. These are found in specialized or precision applications and help OEMs move from one-size-fits-all damping to customized performance.

Business Impact for OEMs

-

Extended Equipment Life

Adaptive damping reduces mechanical stress, excessive vibration, and wear on joints, bushings, frames, and mounting points. The result is longer equipment lifespan and fewer warranty claims.

-

Improved Performance and Efficiency

Automatically tuned dampers help machinery operate smoothly under variable conditions, reduce cycle inconsistencies, and improve precision in automated processes. Better stability means better accuracy and higher productivity.

-

Competitive Product Differentiation

Offering adjustable or automatic damping instantly positions an OEM as more technologically advanced, customer-centric, and focused on longevity and performance. This helps win high-value contracts, especially in Europe and North America where buyers expect advanced engineering.

-

Lower Total Cost of Ownership for End-Users

When OEMs integrate adjustable dampers, end-users benefit from fewer breakdowns, reduced shock-related damage, and longer replacement cycles. This creates a strong commercial selling point that helps OEMs justify premium pricing.

Where Duroshox Fits Into This Evolution

With decades of experience in motion control, Duroshox is strategically positioned to support OEMs transitioning to adaptive damping systems.

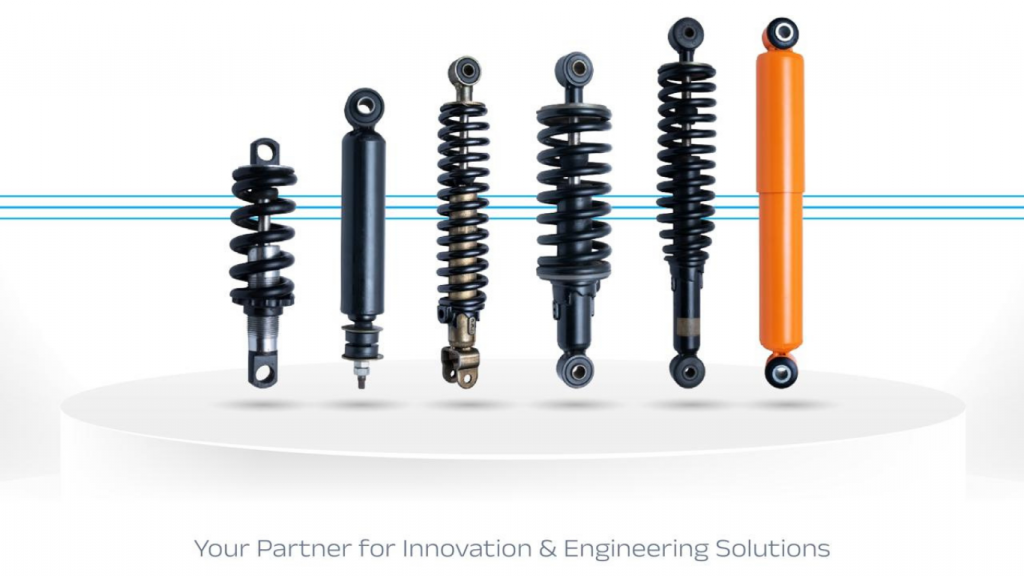

Duroshox’s strengths include custom-designed adjustable shock absorbers tailored to application load, speed, and environment; self-adjusting hydraulic dampers for industrial automation; high-cycle-life solutions for heavy-duty applications; engineering expertise to help OEMs select the right damping curve; and manufacturing capability to scale globally.

Whether an OEM is building forklifts, AGVs, RV components, construction machinery, or industrial equipment, Duroshox provides precision-engineered, application-specific damping solutions that improve performance and reliability.

The Future of Damping Technology

The shift toward adjustable and automatic shock absorbers will accelerate as industries adopt smart machinery with IoT-enabled components, predictive maintenance that reads damping patterns, modular machinery needing flexible motion control, and lightweight vehicle design requiring optimized suspension systems.

OEMs adopting adaptive damping now place themselves ahead of regulatory, technological, and customer expectations.

Adjustable and automatic shock absorbers are not just a new feature; they mark a transition toward smarter, more efficient, and more reliable machinery. For OEMs, this shift brings measurable gains in performance, durability, and customer satisfaction.

For brands that want to stay competitive, partnering with a manufacturer like Duroshox, with capabilities in customizable, high-performance damping solutions, ensures they are prepared for the next decade of innovation.